In the landscape of filtration technologies, the innovation of VLS-patented stainless steel membranes marks a significant advancement over traditional ceramic membranes. Let’s explore why.

Construction Material

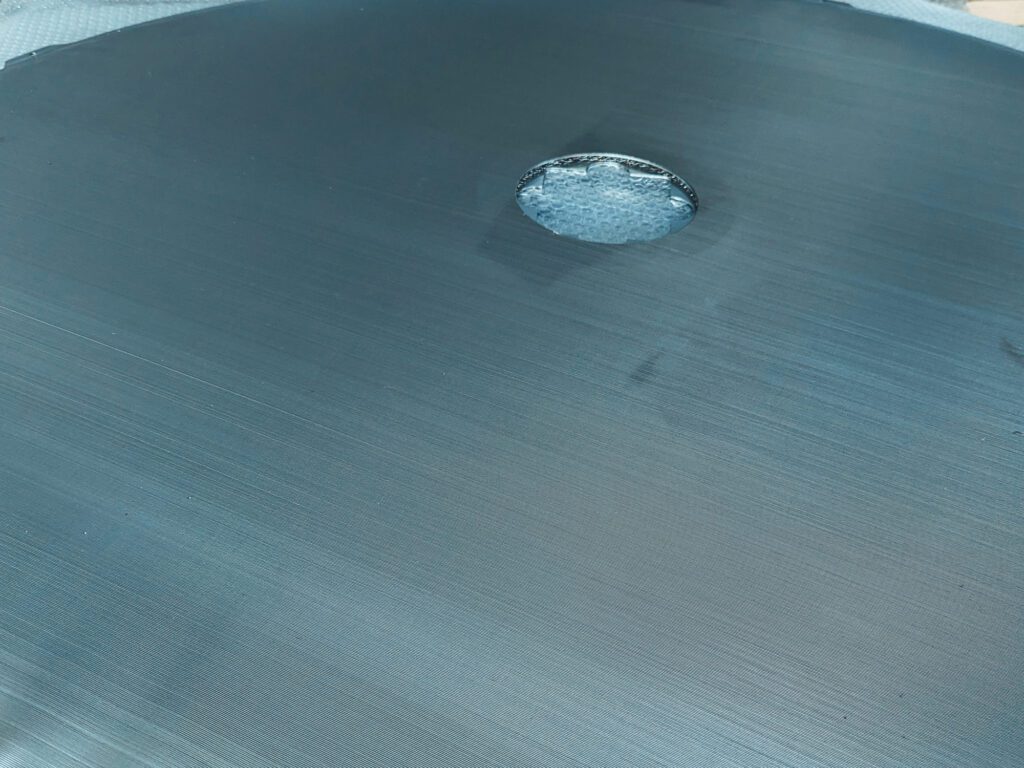

Ceramic membranes require three distinct materials for construction: ceramic, stainless steel vessel, and polymer seals. VLS stainless steel membranes, on the other hand, are entirely made of stainless steel with a thin zirconium coating. This composition ensures optimal material compatibility and superior strength, eliminating the typical fragility of ceramics.

Leak Points:

A critical issue with ceramic membranes is the need for polymer seals at both ends of each module. These points can leak over time, requiring frequent replacements. Stainless steel membranes, due to the welding of porous tubes, do not need seals, drastically reducing leak points and associated costs of maintenance and lost productivity.

Durability:

Ceramic membranes are known for their fragility, prone to cracks and breaks due to rapid temperature or pressure changes. Conversely, stainless steel membranes are extremely robust and require no special care to protect them from mechanical vibrations, pressure shocks, or temperature fluctuations. This translates to greater durability without the need for frequent replacement parts.

Hyper-Concentration:

Another advantage of stainless steel membranes is their better handling of hyper-concentration. With an internal diameter of 9 mm, compared to 6 mm for ceramic membranes, blockages can be rinsed out using a 6 mm diameter lance and water, greatly facilitating maintenance and cleaning.

Higher Wine/Juice Recovery:

The larger diameter of stainless steel membrane tubes allows for higher solid concentration and thus more efficient wine or juice recovery. Thanks to the special configuration of VLS series membranes and the zirconium coating, it is possible to achieve at least 15% higher recovery compared to traditional 6 mm ceramic membranes, given the same filtration time.

Operational Efficiency:

Stainless steel membranes offer greater operational flexibility, allowing for back-pulse and back-flow without the risk of tube breakage or leakage. They also enable operation at higher transmembrane pressures and cross-flow rates, extending filtration runs before the need for chemical cleaning.

In conclusion, VLS zirconium-coated stainless steel membranes represent a true revolution in the filtration sector. They offer greater durability, efficiency, and reduced maintenance costs compared to traditional ceramic membranes. Choosing VLS membranes means investing in cutting-edge technology that guarantees superior performance and long-term reliability.