Campari Argentina has relied again on VLS Technologies and has purchased a ATEX certified 500×500 LFA filter press with 50 plates to be paired with an already bought twin filter for filtering Red Campari. The filter is ATEX certified which is necessary because it is used in an area subjected to explosion risk. For this reason VLS Technologies has made a tailored design for the motorization and the electrical part with the related control board.

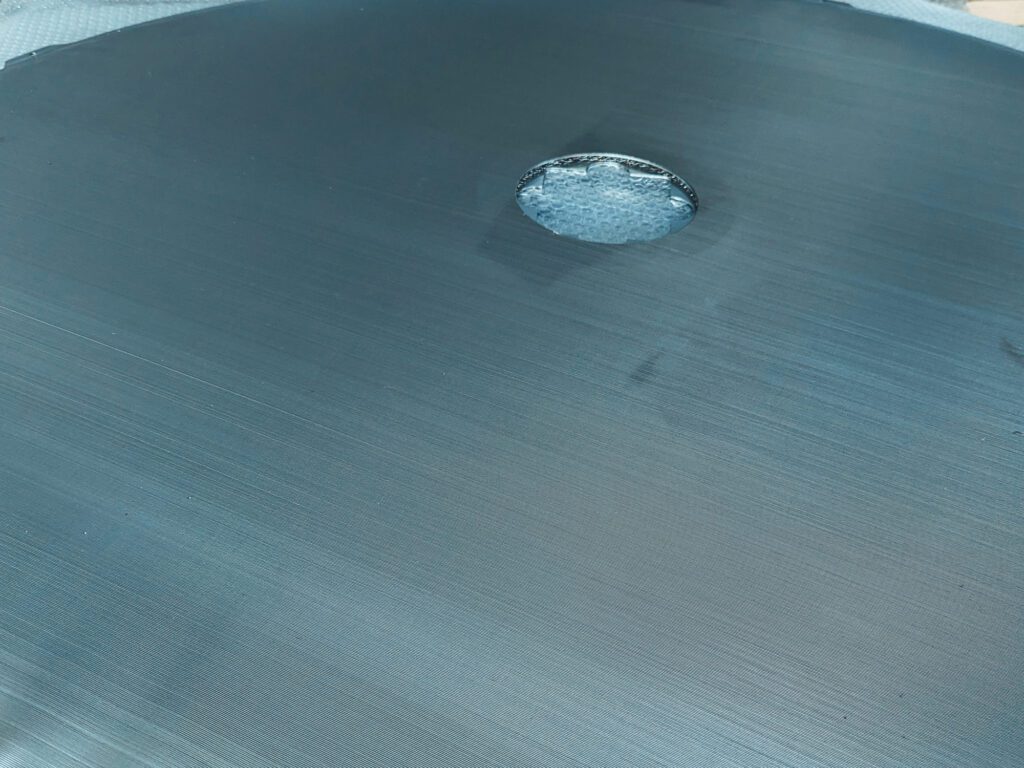

LFA-500×500 press filter

The LFA filters are monobloc units designed for filtering solution with high contents in suspended solids. These filters feature dedicated filtering clothes mounted on recessed plates; through the cloths the product gets rid of solids. The filter press is composed of a mild steel frames (it is possible to cover it entirely in AISI 304 or AISI316 Stainless Steel), concamerated plates and polypropylene cloths, manual closure and feed pump completed with expansion pot in Stainless Steel and automation. The range includes the following sizes: 400×400, 500×500, 630×630, 800×800, 1000×1000, 1200×1200 but other dimensions are available upon request.

ATEX certification

The ATEX name comes from the words Atmosphères ed Explosibles and it is the standard name which groups two EU Directives. The one dedicated to the technical plants is the 2014/34/UE: regulations of devices to be used in areas subjected tor risk of explosion. The Directive applies to manufacturers of devices used in areas with potentially explosive environments and calls for certification of these devices. In the end the Directive imposes the ATEX certification for all the products installed in areas with explosion risks.