The global commerce of juice is growing. Even if the main markets are still China, France, Germany, United Kingdom and USA, some other countries envisage big growth. The fruit and vegetable juices has started become popular with the increase of attention towards healthy food and health. In the current market the orange juice is the more requested globally but other juices are gaining attention. Among them the grapefruit juice, apple juice, tomato juice, other juice and the mixtures.

Two rotary vacuum filters for the Indian market of fruit juices

VLS Technologies has sealed a new partnership with one of the biggest juice producers in India who has bought two 25 sqm rotary drum vacuum filters for filtering apple juice.

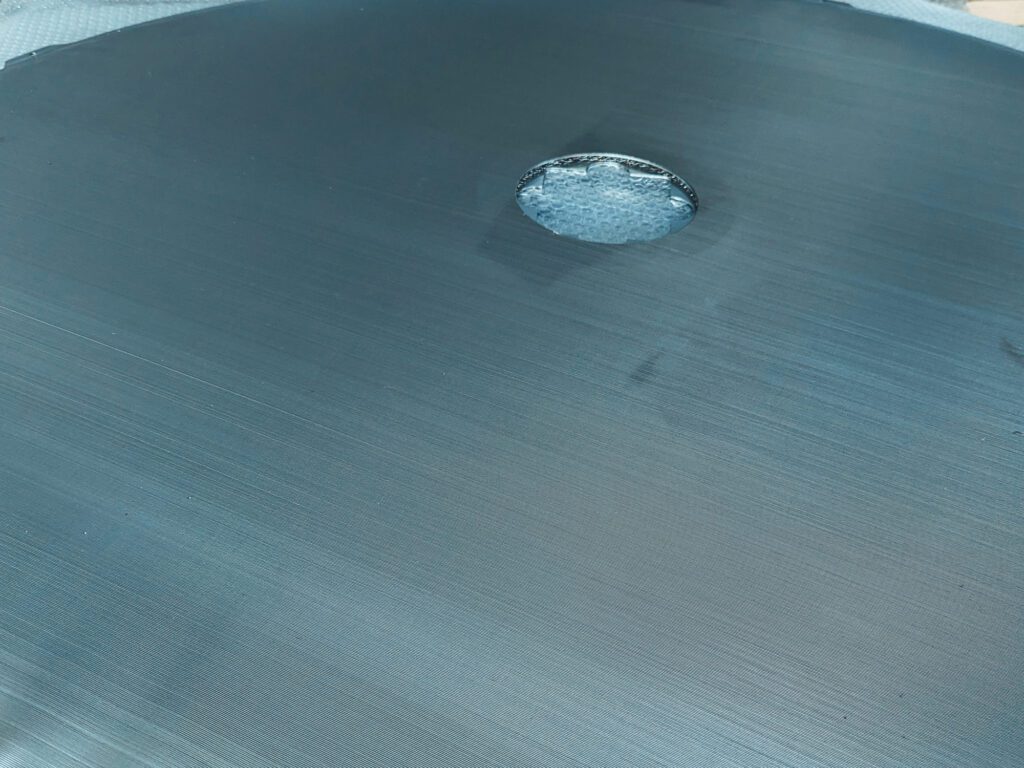

The rotary drum vacuum filters (FRS) have been designed for filtering liquids with a high content in suspended solids thanks to the use of filtering aids such as fossil flour. The machine is entirely built in Stainless Steel (AISI 304 or AISI 316) and it is composed by a rotary drum, a vat to contain the product to be filtered and a dosing tank; it is completed with pumps and instrumentation for the correct functioning. The working principle is to create vacuum inside the drum which is partially submerged in the vat which contains the product to be filtered. This way the liquid pass to the internal part of the drum where a layer of fossil flour filters the juice. VLS Technologies’ range of rotary drum vacuum filters goes from 2,5 to 40 sqm of filtering surface; on demand other dimensions are available.

HPL-30-A Pluma Filter for an italian producer of grape juice

The filter for juice bought by an Italian Company is a 30-cartridges PLUMA FILTER, completely automatic, used for filtering grape juice. The Pluma filters (HPL) are cartridge microfiltration plants who allow to treat the product without using any filtering aid. The machine is completely realized in Stainless Steel (AISI 304 or AISI 316) and completed with a PLC for management and monitoring the filtration and cleaning phases, housings for the filtering cartridges, pumps and all the instrumentation for the correct functioning; it is available both in the semiautomatic and the automatic version. One the advantages is the possibility of using cartridges of different porosities which allow for different steps of filtration so to reach the desired density of the liquid. The range goes from 3 to 30 cartridges but other dimensions are available on demand.